Tips for choosing the right thrust ball bearing

Tips for choosing the right thrust ball bearing

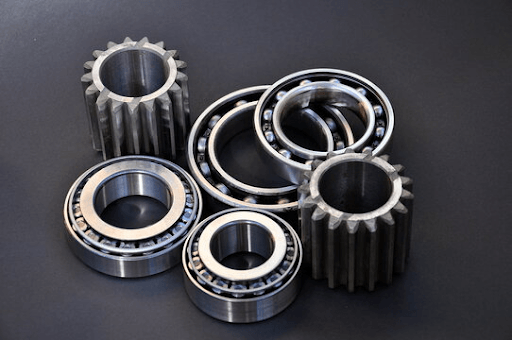

Do you know when people use thrust ball bearings? The thrust bearing is used when you are working on a mechanical project. Ball thrust bearings are made to boost your mechanical efficiency by reducing friction. Several industrial applications frequently use thrust ball bearings to enhance their efficiency. Installing a suitable bearing is essential to get the most out of your equipment.

Using the wrong bearing can reduce efficiency, increase maintenance needs, and, in the worst situations, make equipment failure expensive to repair. The fact is that several bearing types do not simplify your decision-making process. Selecting the right industrial bearings can be difficult.

Here you get a tip for choosing the right thrust ball bearing:

What is a thrust ball bearing?

Thrust ball bearings are a unique class of bearing created to support axial stresses. The components of this kind of bearing are a ball in the centre of a cage between two washers. The washer prevents the ball from moving axially while freely rotating inside the cage. Thrust ball bearings are perfect for high axial load applications like turbines and pumps because of their design. Heavy machinery like mining and construction equipment also makes use of them. Linear bearing is also less complex in their design than other types of bearings, which lowers their cost.

Check for accuracy

Thrust ball bearings can support axial loads in one or two directions. The balls, which roll with very low friction and carry the load, transfer the load between the raceways. Due to their design, thrust ball bearings are not appropriate for heavy radial loads.

To ensure appropriate functioning and precise load support, it is important to choose the right size and type of linear bearings and rails south Africa for your application. The bearing also needs to sustain the required speed and load capacity.

Selecting needle bearings that fit your unique requirements is important since thrust ball bearings are made to offer a high level of precision and accuracy. High-precision thrust ball bearings will perform more consistently and deliver successful results.

Speed

Needle bearings are designed to perform well over a specific range of speeds. A fast-moving system will require different bearings than a slow-moving system. Even if they are slightly out of alignment, high-speed bearings must continue to function securely because this might have a far more substantial impact when turning quickly.

Temperature

To make the most of a spinning system, you must know how temperature changes affect its parts. A system's journal bearing can generate a lot of heat, and how they respond to heat from other sources is also essential. The bearing's lubrication needs to be adjusted for the temperatures it will operate.

Load

The bearing load can be measured in several ways. The right radial load angle is applied to the shaft. Forces that act in the same direction can be measured using axial load. In a system, axial and radial loads can combine to create a moment or combined load. A bearing over the expected range must support all three types of loads.

Conclusion

If you are planning to buy a thrust ball bearing, you can choose a bearing centre that will offer you the best accuracy and speed of the bearing. The above listed are all the few tips you need to consider for selecting the right thrust ball bearing.

We combine our years of expertise with exceptional customer service and the highest quality products. All this assures you of the best experience from start to finish.

Bearing Centre, Blantyre, Southern Region, Malawi, Africa - 312200

Website by Visionar

Subscribe to our newsletter

We will get back to you as soon as possible

Please try again later